S45C Hard Chrome ePlated Piston Rod For Pneumatic Cylinders

I-pneumatic cylinder hydraulic piston rod ikwabizwa ngokuba yintonga ye-chrome-plated.Yintonga enomphezulu ophathwa ngokusila okukhethekileyo kunye ne-chrome plating eqinile.Isetyenziswa ngokubanzi kwiisilinda ezahlukeneyo, iisilinda zehydraulic, ukupakishwa, ukwenziwa kwemithi, ukusonta, ukuprinta kunye noomatshini bokudaya, iinxalenye zokufa kunye nezinye izixhobo zokuhambisa ngokuzenzekelayo ngenxa yobunzima bayo, ezinokwandisa ubomi benkonzo yoomatshini abachanekileyo kunye nezixhobo.

Samkele intonga echanekileyo yokubanda, ukuhonjiswa kunye nokupolisha ukwenza intonga ye-pneumatic hydraulic piston rod, yonke into ekujoliswe kuyo yobuchwephesha ihlangabezana nomgangatho wesizwe.

Ukucaciswa kweenkcukacha

Izixhobo: CK45(GB/T699-1999)

Iinkcukacha zoomatshini:

Amandla okuqina (Mpa):≥600N/mm2

0,2 Uxinzelelo lweSivuno(Mpa):≥355N/mm2

Ubude:min.16%

Ukutyeba kweChrome ePlated: φ<20mm≥15μm,ukusuka kwiφ20mm>20μm

Uburhabaxa: Ra<0.2

Ubulukhuni be-Chrome: 850HV-1050HV

Unyamezelo lweDayimitha: f7,f8

Ukuthe tye: <0.1um/1000mm

I-Ovality: < 1/2 ukunyamezela ububanzi

Uvavanyo loVavanyo lweCorroseston: ISO 10289:1999,IDT

Idayamitha yangaphandle:3-120mm (GCr15) 3-40m(SUS440C)

Umqathango wonikezelo:Eqhelekileyo,Ukuqaliswa Kokuqina,Q+T

Itheyibhile yokwakheka kweekhemikhali

| UHLELO LWEKHEMIKALI(%) | |||||||

| Izinto eziphathekayo | C% | Mn% | Si% | S% | P% | V% | Cr% |

| <= | |||||||

| CK45 | 0.42-0.50 | 0.50-0.80 | 0.17-0.37 | 0.035 | 0.035 | ||

| ST52 | <=0.22 | <=1.6 | <=0.55 | 0.035 | 0.035 | 0.10-0.20 | |

| 20MnV6 | 0.16-0.22 | 1.30-1.70 | 0.1-0.50 | 0.035 | 0.035 | ||

| 42CrMo4 | 0.38-0.45 | 0.60-0.90 | 0.15-0.40 | 0.03 | 0.03 | 0.90-1.20 | |

| 4140 | 0.38-0.43 | 0.75-1.0 | 0.15-0.35 | 0.04 | 0.04 | 0.80-1.10 | |

| 40Cr | 0.37-0.45 | 0.50-0.80 | 0.17-0.37 | 0.80-1.10 | |||

| Ububanzi | Ubunzima | Ukunyamezelana | Ukunyamezelana | Ukunyamezelana |

| mm | Kg/m | f7 (μm) | f8(μm) | h6(μm) |

| 6 | 0.22 | -10--22 | -10--28 | 0--9 |

| 8 | 0.39 | -13--28 | -13--35 | 0--9 |

| 10 | 0.62 | -13--28 | -13--35 | 0--11 |

| 12 | 0.89 | -16--34 | -16--43 | 0--11 |

| 16 | 1.58 | -16--34 | -16--43 | 0--11 |

| 18 | 2.00 | -16--34 | -16--43 | 0--13 |

| 20 | 2.47 | -20--41 | -20--53 | 0--13 |

| 22 | 2.99 | -20--41 | -20--53 | 0--13 |

| 25 | 3.86 | -20--41 | -20--53 | 0--13 |

| 28 | 4.84 | -20--41 | -20--53 | 0--13 |

| 30 | 5.55 | -20--41 | -20--53 | 0--16 |

| 32 | 6.32 | -25--50 | -25--64 | 0--16 |

| 36 | 8.00 | -25--50 | -25--64 | 0--16 |

| 38 | 8.91 | -25--50 | -25--64 | 0--16 |

| 40 | 9.87 | -25--50 | -25--64 | 0--16 |

| 45 | 12.49 | -25--50 | -25--64 | 0--16 |

| 50 | 14.22 | -25--50 | -25--64 | 0--19 |

| 55 | 15.43 | -30--60 | -30--76 | 0--19 |

| 60 | 18.66 | -30--60 | -30--76 | 0--19 |

| 65 | 26.07 | -30--60 | -30--76 | 0--19 |

| 70 | 30.23 | -30--60 | -30--76 | 0--19 |

| 75 | 34.71 | -30--60 | -30--76 | 0--19 |

| 80 | 39.49 | -30--60 | -30--76 | 0--22 |

| 85 | 44.58 | -36--71 | -36--90 | 0--22 |

| 90 | 49.98 | -36--71 | -36--90 | 0--22 |

| 95 | 55.68 | -36--71 | -36--90 | 0--22 |

| 100 | 61.70 | -36--71 | -36--90 | 0--22 |

Yintoni imigangatho yokunyamezela i-f7 kunye ne-f8:

Uluhlu lonyamezelo lwe-f8 lukhulu kunolo lwe-f7, kwaye ukufakela kuxhomekeke kwinqanaba elihambelana nomngxuma wokunyamezela.Umzekelo, xa ubungakanani obusisiseko buyi-10-18, f8(-0.016,-0.034), f7(-0.016,-0.027), ukutenxa kweendlela ezimbini zokunyamezelana kuyafana, uluhlu lwe-f7 luncinci, kunye nokucocwa. uluhlu lofakelo lofako luncinci.

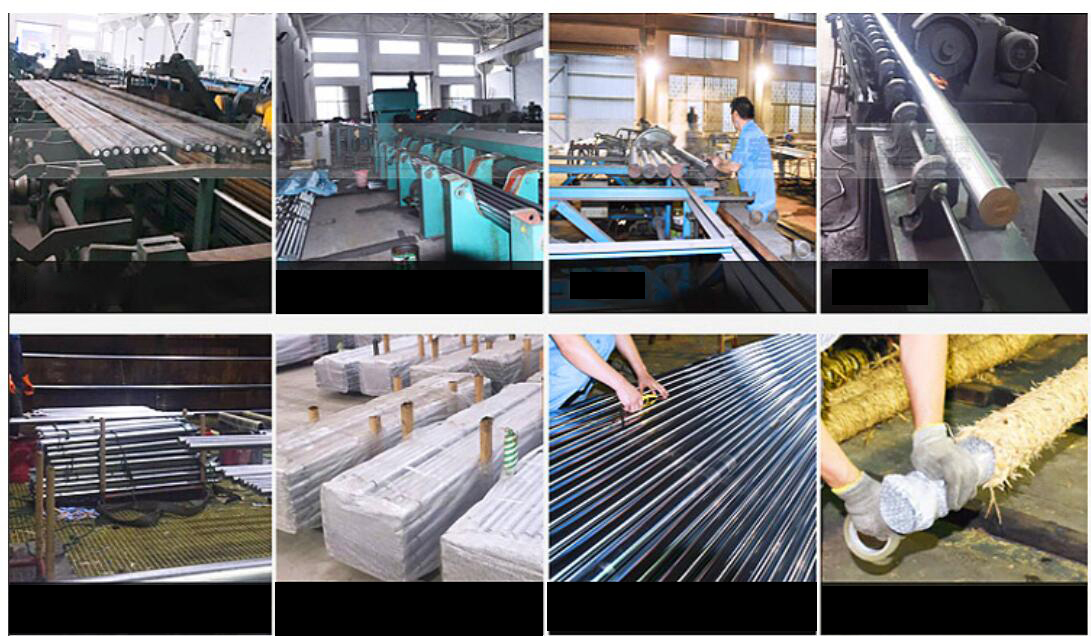

Ukuhamba kweMveliso

Inyathelo loku-1: Ukukrola/Ukuzotywa okubandayo:

Umzobo obandayo yiteknoloji yokucubungula ye-pneumatic cylinder piston rod.Kwi-cylinder ye-pneumatic hard chrome plated rod, umzobo obandayo ubhekisela kumzobo phantsi kwemeko yobushushu obuqhelekileyo ukuze kuphunyezwe imilo ethile kunye neempawu ezithile zoomatshini.Xa kuthelekiswa nokubumba okushushu, iimveliso ezitsalwa ngokubanda zineengenelo zokuchaneka komgangatho ophezulu kunye nokugqiba okungcono komphezulu.

2 Inyathelo: Ukulungelelanisa

Eli nyathelo sinokuqinisekisa ukuba intonga eqinileyo ye-chrome ilungile ngokwaneleyo.Kubaluleke kakhulu, xa uyifaka ngaphakathi kwi-cylinder ye-pneumatic.Ukuthe tye okusemgangathweni yi-0.2mm/m.

Inyathelo lesi-3: Ukuhombisa

Ukucutshungulwa kwe-Honing yindlela esebenzayo yokucubungula eyenza i-pneumatic cylinder piston rod surface ifezekise ukuchaneka okuphezulu, umgangatho ophezulu kunye nobomi obude.Inokuphucula ngokufanelekileyo ukuchaneka kwe-dimensional, ukuchaneka kwemilo kunye nokunciphisa ixabiso le-Ra, kodwa ayikwazi ukuphucula indawo yomngxuma kunye nezinye iindawo.

Inyathelo lesi-4: Ukupholisha ngentonga yentsimbi

Ukupholisha kubhekiselele ekusetyenzisweni komatshini, iikhemikhali okanye iziphumo ze-electrochemical ukunciphisa uburhabaxa bomphezulu wentonga ye-pneumatic cylinder piston ukufumana indawo eqaqambileyo negudileyo.Kukusetyenziswa kwezixhobo zokupholisha kunye namasuntswana abrasive okanye enye imidiya yokupolisha ukuguqula umphezulu wentonga yepiston yesilinda yepneumatic.

5 Inyathelo: I-Chrome Plating

I-Chrome plating ibhekiselele kwisenzo sokucwenga ichromium njengokwaleka kwintonga ecwecwe yechrome elukhuni yomoya.

I-Chromium-plated layer inobunzima obuphezulu kakhulu, kwaye ubunzima bayo bunokwahluka phakathi koluhlu olubanzi lwe-400-1200HV ngokubunjwa kwesisombululo se-plating kunye neemeko zenkqubo.I-chrome-plated layer inokumelana nokushisa okulungileyo.Xa ishushu ngaphantsi kwe-500 ℃, akukho tshintsho lucacileyo kwiglosi kunye nokuqina.Iqondo lobushushu lizakuqala ukuba yi-oxidize kwaye litshintshe umbala xa ubushushu bungaphezulu kwe-500℃, kwaye ukuqina buyakwehla xa bungaphezulu kwe-700℃.I-coefficient ye-friction ye-chrome layer incinci, ngakumbi i-coefficient eyomileyo ye-friction, eyona iphantsi phakathi kwazo zonke iintsimbi.Ke ngoko, umaleko we-chrome-plated unokumelana nokunxiba kakuhle.

Umaleko wokucwenga wechromium unozinzo oluhle lweekhemikhali.Ayinayo impembelelo kwi-alkali, i-sulfide, i-nitric acid kunye neyona nto ininzi ye-organic acids, kodwa inokuchithwa kwi-pneumatic acid (njenge-pneumatic acid) kunye ne-asidi ye-sulfuric eshushu.Kuluhlu lokukhanya olubonakalayo, ukubonakaliswa kwe-chromium malunga ne-65%, ephakathi kwesilivere (88%) kunye ne-nickel (55%).Ngenxa yokuba i-chromium ayitshintshi umbala, inokugcina ukubonakala kwayo ixesha elide kwaye ingcono kunesilivere kunye ne-nickel.

Inyathelo lesi-6: I-Chrome plated intonga yokupholisha emva kokubekwa

I-Electroplating kunye nokupolishwa: ziindlela ezimbini ezahlukeneyo zokunyanga umphezulu wesinyithi kunye nezinye izinto.Olokuqala lunyango lwekhemikhali, kwaye lo mva lunyango lomatshini.

I-Electroplating: Inkqubo yokusebenzisa i-electrolysis ukuncamathisela umaleko wefilimu yesinyithi kumphezulu wesinyithi okanye ezinye izinto.Inokuthintela ukubola, ukuphucula ukumelana nokunxiba, ukuhanjiswa kombane, ukubonakalisa kunye nokuphucula ubuhle.

Ukupholisha: Sebenzisa izixhobo zokugudisa eziguquguqukayo kunye namasuntswana abrasive okanye enye imidiya yokupholisha ukuguqula umphezulu wesixhobo sokusebenza.Ukucwenga akukwazi ukuphucula ukuchaneka kwe-dimensional okanye ukuchaneka kwejometri ye-workpiece, kodwa ijolise ekufumaneni umphezulu ogudileyo okanye iglosi yesibuko.

7 Inyathelo: UVavanyo loMgangatho we-Chrome plated rod

Iintonga zepiston eziye zenziwa i-electroplating kunye neenkqubo zokupholisha zihlala zihamba kunye neziphene zokugquma ezifana nemigodi ye-chrome kunye ne-pitting.Ubungakanani kunye nobuninzi bezi ziphene zichaphazela ngokuthe ngqo ukusebenza kwentonga yepiston.Ukunciphisa impembelelo yezi ziphene kwintonga yepiston, kwelinye icala, ngokuphucula umgangatho wezinto ezibonakalayo, ukuphucula iteknoloji yokucubungula, kunye nokunciphisa ukwenzeka kweziphene;ngakolunye uhlangothi, kuyimfuneko ukufumanisa ngokuchanekileyo iziphene ze-plating emva kwenkqubo yokupholisa ukuphepha iimveliso ezingafanelekanga ekuphumeni kwefektri.Iinjineli ze-Autoair zifumanisa ukuba isiphene sizenzekela ngoncedo lolwazi lwesayensi yemifanekiso

8 Inyathelo: Ukupakisha

FAQ:

Q1:Yintoni intonga yepiston ye-pneumatic cylinder?

A: Intonga yepiston yinxalenye esisiseko kunye nebalulekileyo kuyo yonke i-hydraulic okanye icylinder yepneumatic.Intonga yepiston ngokuqhelekileyo bubude obuchanekileyo bomatshini obuqinileyo be-chrome efakwe kwintsimbi ebandayo egqityiweyo ehambisa amandla adalwe yipiston kumatshini wokwenza umsebenzi.

I-Q2: Uthini umgaqo we-pneumatic cylinder piston rod?

A: Ipiston ye-pneumatic cylinder kwi-cylinder ithwala ukutyhala okanye ukutsalwa kwamandla okwenziwa luxinzelelo lomoya, kwaye isebenza ngokuthe ngqo kwintonga ye-pneumatic cylinder piston edityaniswe nepiston, emva koko intonga ye-pneumatic cylinder piston iqhagamshelwe kwindawo yokusebenza yomthwalo ukuze ihambe. ukuya Nobuya.

Q3:Yintoni imathiriyeli ekrwada yentonga yakho ye-pneumatic cylinder piston

A: Ngesiqhelo, intonga yepiston ye-pneumatic ye-cylinder ye-pneumatic iya kukhetha i-45 # yentsimbi njengento ekrwada.Ukuba i-cylinder eveliswayo kufuneka isetyenziswe kwindawo ekhethekileyo, i-304 insimbi engenasici nayo ingasetyenziswa

Q4: Kutheni ukhethe 45 # intsimbi njengento ekrwada

A: 45 # intsimbi yintsimbi ephezulu ye-carbon structural enobunzima obuphantsi kunye nokusika okulula.Emva kokucima, ukuqina kwayo komphezulu kunokufikelela kwi-45-52HRC.Kwaye inokuba nokusebenza okungcono kokusika kunye namandla aphezulu, ukuqina kunye nezinye iipropathi ezibanzi zoomatshini, ke yenye yezinto ezisetyenziswa ngokuqhelekileyo kwiindawo zeshaft.

I-Q5:Yintoni inkqubo yokwenza intonga yakho ye-pneumatic cylinder piston?

A: Ukuze ufumane umgangatho ozinzileyo womatshini, ukulungiswa kwentonga ye-piston akuvumelekanga emva kokuba umatshini uqalile.Ngoko ke, inkqubo yokulungelelanisa kufuneka iqhutywe phambi komatshini.Ngenxa yobunzima bobunzima be-workpiece, ukujika okukrakra kunye nokujika okulungileyo kufuneka kuqhutywe ngexesha lomatshini wokuphucula ukuchaneka komatshini.Imowudi yokusebenza yentonga yepiston ibuyisela intshukumo yomgca.Ukuze kuphuculwe ubomi benkonzo yentonga yepiston, umphezulu kufuneka ube yi-chrome-plated ukuze kuphuculwe ubunzima bomhlaba kunye nokumelana nokugqoka.Emva kokufakwa kwe-chrome, unyango lokupolisha luyafuneka ukufumana uburhabaxa obuphezulu bomphezulu, ukunciphisa i-friction factor, kunye nokuphucula ukusebenza kokutywinwa.Kuba inkqubo yokupolisha iphantse ingabinampembelelo kububanzi bangaphandle bentonga yepiston, i-workpiece kufuneka ifezekise uburhabaxa obuphezulu bomphezulu phambi kokubekwa kwe-chrome.Ngoko ke, kuyimfuneko yokongeza inkqubo yokugaya kakuhle ngaphambi kokuba inkqubo ye-chrome plating (ukugaya ngokuchanekileyo kunokuphucula ukunamathela komphezulu wechromium. ).Ngokusekwe kolu hlalutyo lungentla, ezona nkqubo zifanelekileyo zokusetyenzwa kwentonga yepiston zezi: i-strateining-rough turning-fine turning-fine grinding-chrome plating-polishing.

I-Q6: Yintoni ukupoliswa kwentonga ye-pneumatic cylinder piston

A: Ngexesha lenkqubo yokujika, umngxuma ophakathi odlala indima yokumisa uya kubonisa iqondo elithile lokunxiba.Ukuze kuqinisekiswe umgaqo odityanisiweyo weebenchmarks, umngxuma ophakathi kufuneka unqunywe ngaphambi kokugaya ukuqinisekisa umgangatho wokucubungula.Xa ukugaya, ukugaya uvavanyo kufuneka kuqhutywe kwisangqa sangaphandle kufuphi nesiphelo sokuqala, kwaye ukugaya intonga ye-piston kunokwenziwa kuphela xa imeko yokuphuma ihlangabezana neemfuno zokucubungula.Ukongeza ekuphuculeni ukuchaneka kwe-dimensional, inkqubo yokusila ecolekileyo ikwafuna ukufumana uburhabaxa obuphezulu kumphezulu owenziwe ngomatshini ukuze kuphuculwe ukudityaniswa kwee-ion zechromium ngexesha lenkqubo ye-electroplating.Ukuze kuqinisekiswe ukuba ubukhulu bomaleko wechromium wokucwenga wentonga yokugqibela yepiston bufana, uburhabaxa bomphezulu emva kokusila kakuhle kufuneka busondele kuburhabaxa bomphezulu emva kokubekwa kwechromium kunye nokupholisha.Ukuba uburhabaxa bomphezulu bentonga yepiston bufuneka ukuba bube buphezulu, njengeRa <0.2 μm, kufuneka bucocwe kakuhle.Yongeza inkqubo yokugaya okanye yokupolisha emva kokusila.